|

|

|

|

|

|

|

|

|

|

|

"ARC" REFLECTIVE OPTICAL COATINGS

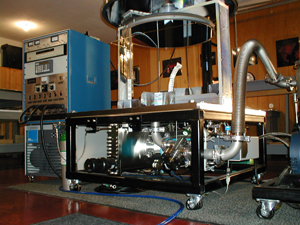

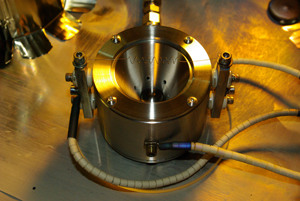

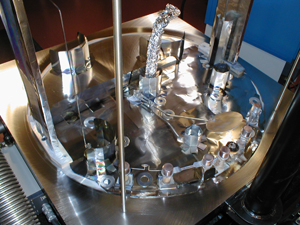

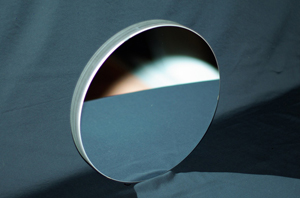

Galaxy Optics has earned its reputation as a leader in precision mirror fabrication and optical coating, trusted by observatories, researchers, and dedicated enthusiasts. Our advanced thin film PVD coating system is engineered specifically for telescope mirrors, delivering exceptionally uniform layer thickness from center to edge and consistently superior optical performance. At the core of our coating technology is ARC "Activated Reactive Coating". ARC is based on the same principles as "Ion Assisted Deposition", the controlled ionization of pure oxygen or other reactive or inert gases into a high energy plasma at very low pressure. This activated ionized gas environment is essential for producing the highest quality aluminum overcoat layers used in astronomical optics.

Galaxy Optics has earned its reputation as a leader in precision mirror fabrication and optical coating, trusted by observatories, researchers, and dedicated enthusiasts. Our advanced thin film PVD coating system is engineered specifically for telescope mirrors, delivering exceptionally uniform layer thickness from center to edge and consistently superior optical performance. At the core of our coating technology is ARC "Activated Reactive Coating". ARC is based on the same principles as "Ion Assisted Deposition", the controlled ionization of pure oxygen or other reactive or inert gases into a high energy plasma at very low pressure. This activated ionized gas environment is essential for producing the highest quality aluminum overcoat layers used in astronomical optics.

How the "ARC" Coating Process Works:

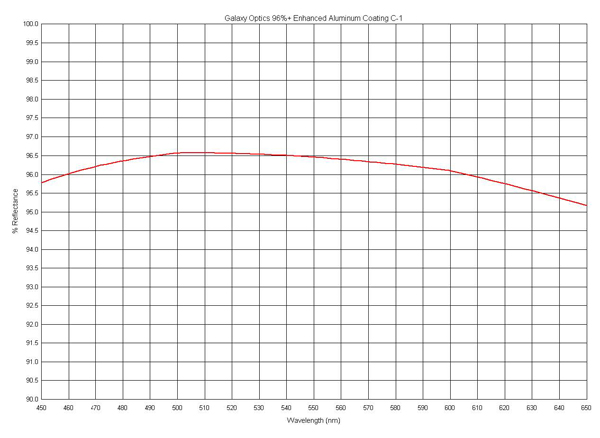

Enhanced reflectivity telescope mirror coatings rely on refractory metal oxide compounds such as silicon monoxide and titanium monoxide. To achieve the desired optical properties, silicon dioxide for low refractive index and titanium dioxide for high refractive index, the monoxide starting materials must be fully oxidized during deposition. The ARC process drives this oxidation to completion, ensuring the formation of exceptionally transparent films with low extinction coefficients. ARC delivers two critical advantages: Complete oxidation produces coatings that are brilliantly clear and free from unwanted coloration. High energy molecular impact forces silicon dioxide and titanium dioxide to form densely packed, extremely hard layers, resulting in exceptional durability. This is the same coating technology trusted in the manufacture of optics for high energy laser systems brought to the world of astronomy to deliver unmatched clarity, longevity, and performance. Every coating produced by Galaxy Optics undergoes rigorous verification using an RGB laser diode reflectometer, ensuring each mirror meets or exceeds its specified reflectivity. When you choose Galaxy Optics, you are choosing coatings engineered for brilliance, built for endurance, and proven through precision testing.

Enhanced reflectivity telescope mirror coatings rely on refractory metal oxide compounds such as silicon monoxide and titanium monoxide. To achieve the desired optical properties, silicon dioxide for low refractive index and titanium dioxide for high refractive index, the monoxide starting materials must be fully oxidized during deposition. The ARC process drives this oxidation to completion, ensuring the formation of exceptionally transparent films with low extinction coefficients. ARC delivers two critical advantages: Complete oxidation produces coatings that are brilliantly clear and free from unwanted coloration. High energy molecular impact forces silicon dioxide and titanium dioxide to form densely packed, extremely hard layers, resulting in exceptional durability. This is the same coating technology trusted in the manufacture of optics for high energy laser systems brought to the world of astronomy to deliver unmatched clarity, longevity, and performance. Every coating produced by Galaxy Optics undergoes rigorous verification using an RGB laser diode reflectometer, ensuring each mirror meets or exceeds its specified reflectivity. When you choose Galaxy Optics, you are choosing coatings engineered for brilliance, built for endurance, and proven through precision testing.

Standard Galaxy Optics Coatings:

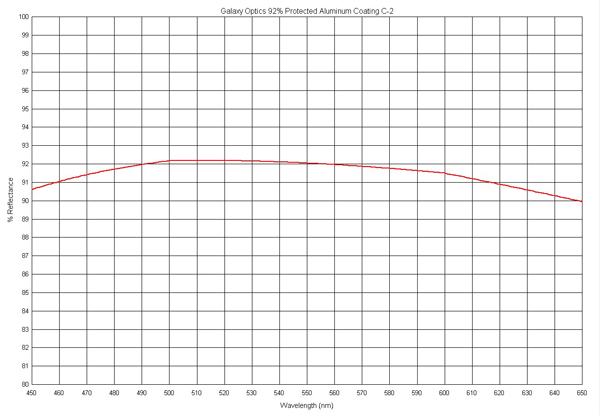

C-1 & C-3 @ 45 AOI : ~ 95% average visual reflectivity, Enhanced Aluminum

C-2 & C-4 @ 45 AOI : ~ 91% average visual reflectivity, Quartz Protected Aluminum

Custom Optical Coatings:

We can produce thin film optical coatings to meet your wavelength specifications from UV to IR. Please contact us for a quote.

Pricing:

C-1 and C-2 Primary Mirror Coatings

|

Diameter *

|

C-1

|

C-2

|

|

14.5"

|

$ 500

|

$ 475

|

|

16.0"

|

$ 550

|

$ 525

|

|

18.0"

|

$ 700

|

$ 675

|

|

20.0"

|

$ 900

|

$ 875

|

|

22.0" **

|

$ 1100

|

$ 1075

|

|

24.0" **

|

$ 1500

|

$ 1475

|

|

|

|

* Non-standard mirror diameters add $50.00 for mounting fixture-tooling surcharge. ** Maximum Edge Thickness: 1.6"

|

C-3 and C-4 : 45 AOI Elliptical Diagonal Mirror Coatings

|

|

M.A. Diameter

|

C-3 @ 45 AOI

|

C-4 @ 45 AOI

|

|

2.60"

|

$ 150

|

$ 125

|

|

3.10"

|

$ 150

|

$ 125

|

|

3.50"

|

$ 200

|

$ 175

|

|

4.00"

|

$ 250

|

$ 225

|

|

4.50"

|

$ 300

|

$ 275

|

|

5.00"

|

$ 350

|

$ 325

|

|

5.50"

|

$ 375

|

$ 350

|

|

6.00"

|

$ 425

|

$ 400

|

|

6.50"

|

$ 450

|

$ 425

|

|

|

Notice:

|

Primary Mirror Coating Removal and Cleaning Service: $100

Diagonal Mirror Coating Removal and Cleaning Service: $50

Galaxy Optics uses a dilute solution of hydrochloric acid and copper sulfate to remove your old coating. This solution safely removes the old coating without affecting the underlying glass or optical figure.

Additional discounts for bulk optical coating orders are available.

Please contact Galaxy Optics for a quote and delivery schedule.

|

|

|

|

|

|

|

Home ~ Reflective Coating Services ~ Ordering & Shipping

Image Gallery ~ Contact Us ~ Customer Comments

All content and images © 2026 Galaxy Optics

Background Picture: M13 By David Childree